Microsoft’s Breakthrough Cooling System Revolutionizes Tech Industry

Microsoft is trailblazing the technology arena with the evolution of its cutting-edge cooling system that employs microfluidics. This innovative method involves the delivery of a liquid coolant right into the silicon, enhancing the cooling process. The efficiency of this remarkable technology is demonstrated by its ability to dissipate heat up to thrice as efficiently as cold plates, a current high-end cooling mechanism prevalent in modern data centers.

The advent of AI and the continuous upliftment in chip designs are advancing the technology world at an unprecedented pace. The consequential heat generated by state-of-the-art chips employed in data centers to run these AI marvels is significantly higher than that of their predecessors. Nonetheless, it’s important for these electronic components to be maintained at moderate temperatures, as excessive heat can cause damage.

The heat produced by the current crop of chips presents a significant challenge, threatening to stagnate the progression of AI technology within a few years. This imminent revolution necessitates a significant upgrade to cooling technology in order to keep up with the inevitable evolution. The competence of Microsoft’s novel cooling system lies in its exceptional cooling capacity, which outperforms the prevalent cold plates by removing heat three times more effectively.

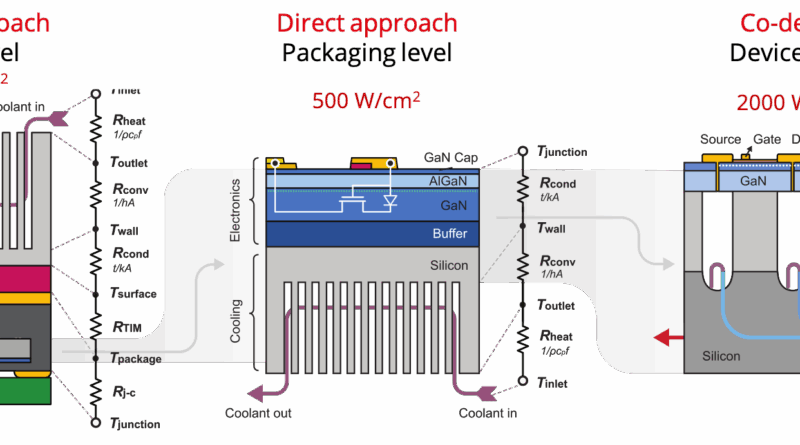

Microsoft’s cooling system employs the mechanics of microfluidics in an unusual but effective fashion. By introducing the coolant directly into the silicon, the warmth generated within the chip can be mitigated right at the source. Precision-etched tiny channels on the chip’s back facilitate this targeted coolant flow directly onto the chip, ensuring a more effective heat dispersal.

Another significant advantage of Microsoft’s cooling system is its deployment of AI to enhance its operation. AI is utilized to pinpoint the unique heat signatures across the chip’s surface. With this precise identification, the coolant can be steered more effectively and targeted at the areas of greatest heat.

Moreover, news has emerged that e-commerce giant Amazon has joined the race to advance cooling technology. The Web Services division of the company announced that it has developed an exclusive liquid cooling system tailor-made for its data centers, all within the span of a year.

Amazon’s pursuit for the best liquid cooling solution to suit the unique needs of its Web Services division led to the consideration of several options available in the market. However, none of the off-the-shelf versions were deemed suitable. This led to the decision to create a custom design, a solution that was more fitting for the requirements of Amazon Web Services (AWS).

Amazon’s approach to this issue is characterized by its emphasis on a direct-to-chip cooling method. The strategy involves placing a cold plate directly over the chip. A set of tubes running through this sealed plate then contain the liquid coolant. As a result, the overheated chip has the heat absorbed and carried away by the cooling liquid, which is channeled out of the server rack.

The ingenuity of this cooling system design conceived by Amazon can be attributed to its efficiency. It took the Amazon team just eleven months to progress from concept to the delivery of the first production unit. This highly accelerated timeline incorporated not just the design and development phase, but also the creation of a dedicated supply chain, the authoring of control software for the systems, rigorous testing of every aspect, and system manufacturing.